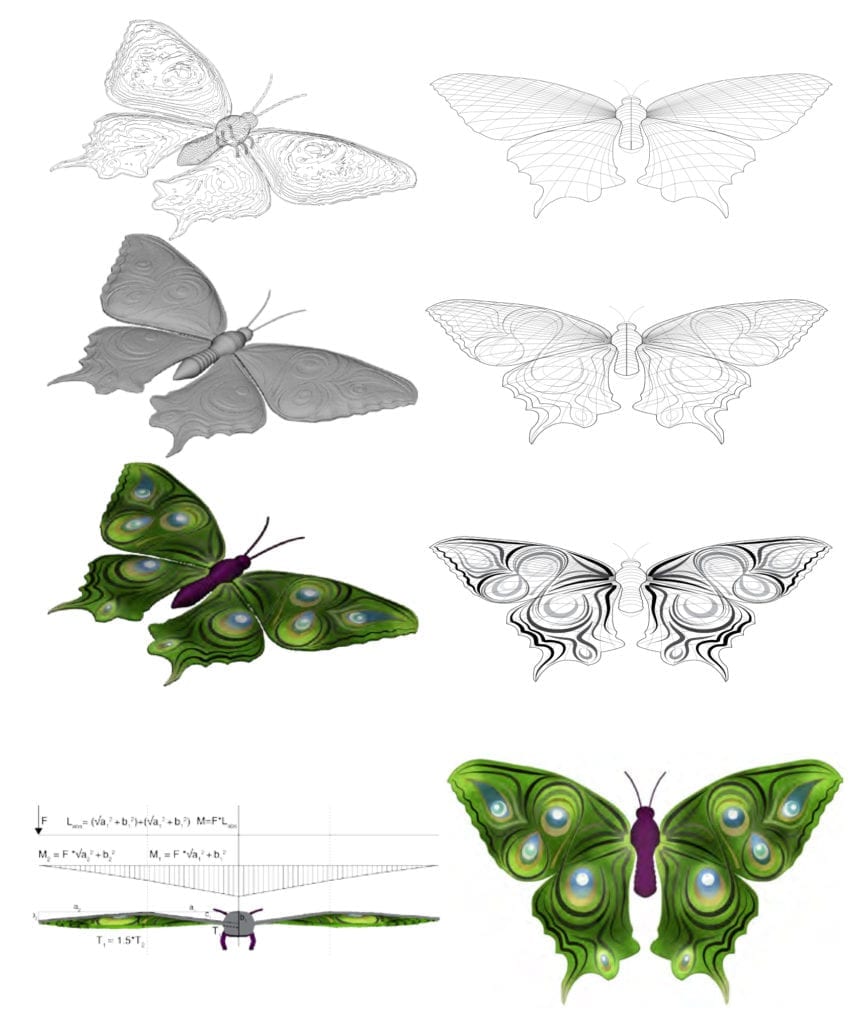

A 3D printer produces a physical analogy of a virtual object. In the additive 3D printing process, the carrier material (in this case gypsum) is bonded layer by layer. Every layer contributes a part to the style of the end product.

Stabilized with epoxy resin, it produces a different hue depending on the number of layers or density of the material and the incidence of the light. 3D printers produce their own aesthetics, which is characterized by the layering and the strips of the printing direction.

Through the lithographic production process the objects are obtained, a watercolor surface drawn like a brush. The more complex and fragile the object is, the more sophisticated the craft of 3D printing becomes.

The 3D-printed object becomes vivid with the texture, since it adds the natural shading of the object accentuated. The expression of such objects thus falls into the three-dimensionally as an object or two-dimensionally as an image read.

Stereolithography is a living process. It is experienced either in the consideration of the 3D printing itself or at the finished object, with the inclusion of light and time.

Each layer of the 3D printed object absorbs a fraction of a time-limited light incident. Increasing the exposure time penetrates the light the longer the more layers all the way until only a few relics remain untouched by the light.